Basic Info

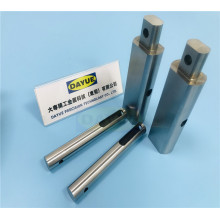

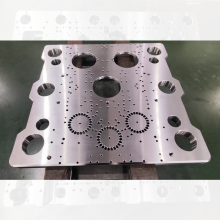

Model No.: Customized

Click on the follow link to find out more information: https://www.zhongyangscrew.com/extruder-screw-and-barrel/

Company Info

- Company Name: Zhejiang Zhongyang Screw Manufacturing Co., Ltd.

- Representative: JUNBING YANG

- Product/Service: Screw Element And Segmented Barrel , Injection Molding Machine Screw Barrel , Single Extruder Screw Barrel , Extruder Screw And Barrel , Screw And Barrel , Extruder Single Screw Barrel

- Capital (Million US $): 5,000,000RMB

- Year Established: 2009

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 31% - 40%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 6

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: XIHOU INDUSTRIAL PARK ,JINTANG TOWN,ZHOUSHAN ,CHINA

- Contact Person: Ms. Mia

- Tel: 86-580-8055067

Premium Related Products

Hot Products

high manganese crusher partscone crusher partsmining equipment from HYMAK mini hydraulic cone crusher stone crusherquarry crusher sand crusher machine quartz crusher price70 TPH crushing plantsymons parts bowl linder good quanlity cone crusher spare parts wearing partsgood quanlity cone crusher spare parts wearing partsPEF0609 professional global supplier large yeild jaw crusher and partsPEF0609 professional global supplier large yeild jaw crusher and partsNewly High Quality Iron Ore MachineryHot Sale High Quality symons cone crusher manualHigh Quality symons cone crusher with Best PriceGood Price of Spring Cone CrusherHigh Quality Spring Cone crusher PriceY250 high performance single cylinder hydraulic systerm-cone crusherY315 high performance single cylinder hydro-cone crusher